WBL250F Metal Lathe 10″ x 22″ Benchtop Brushless Lathe Variable Speed 50 – 2000 RPM 1.5HP

Introducing the WEISS WBL250F Metal Lathe: Precision, Power, and Performance for Your Workshop

Are you in search of a high-quality metal lathe that combines precision, power, and versatility? Look no further than the WEISS WBL250F Metal Lathe. With its impressive features and expertly designed structure, this benchtop brushless lathe is built to meet the demands of professional machinists and hobbyists alike. Let’s explore the key features that make the WEISS WBL250F an exceptional choice for your machining needs.

Unparalleled Precision:

The WEISS WBL250F is engineered with meticulous attention to detail, ensuring exceptional precision in every operation. Its rigid cast-iron construction provides stability and reduces vibrations, resulting in superior surface finishes and accuracy. The lathe’s precision-ground, induction-hardened bed ensures minimal deflection, allowing you to achieve precise cuts and turn intricate designs with ease.

Variable Speed Control:

Equipped with a powerful 1.5HP brushless motor, the WEISS WBL250F offers a variable speed range from 50 to 2000 RPM. This wide speed range enables you to tackle a diverse range of materials, from soft plastics to tough metals, with optimal control. Adjusting the speed is a breeze, allowing you to adapt to different cutting requirements and achieve the desired results.

User-Friendly Operation:

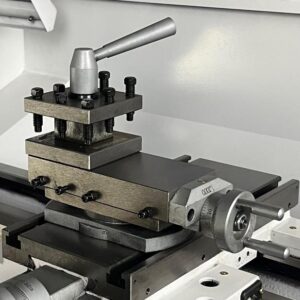

Designed with user convenience in mind, the WEISS WBL250F features intuitive controls and easy-to-read dials. The lathe’s digital speed display allows for precise RPM monitoring, ensuring consistent performance throughout your machining projects. The quick-change tool post facilitates swift tool changes, saving you valuable time and effort. With its ergonomic layout and user-friendly interface, the WEISS WBL250F enhances your productivity and overall machining experience.

Generous Capacity:

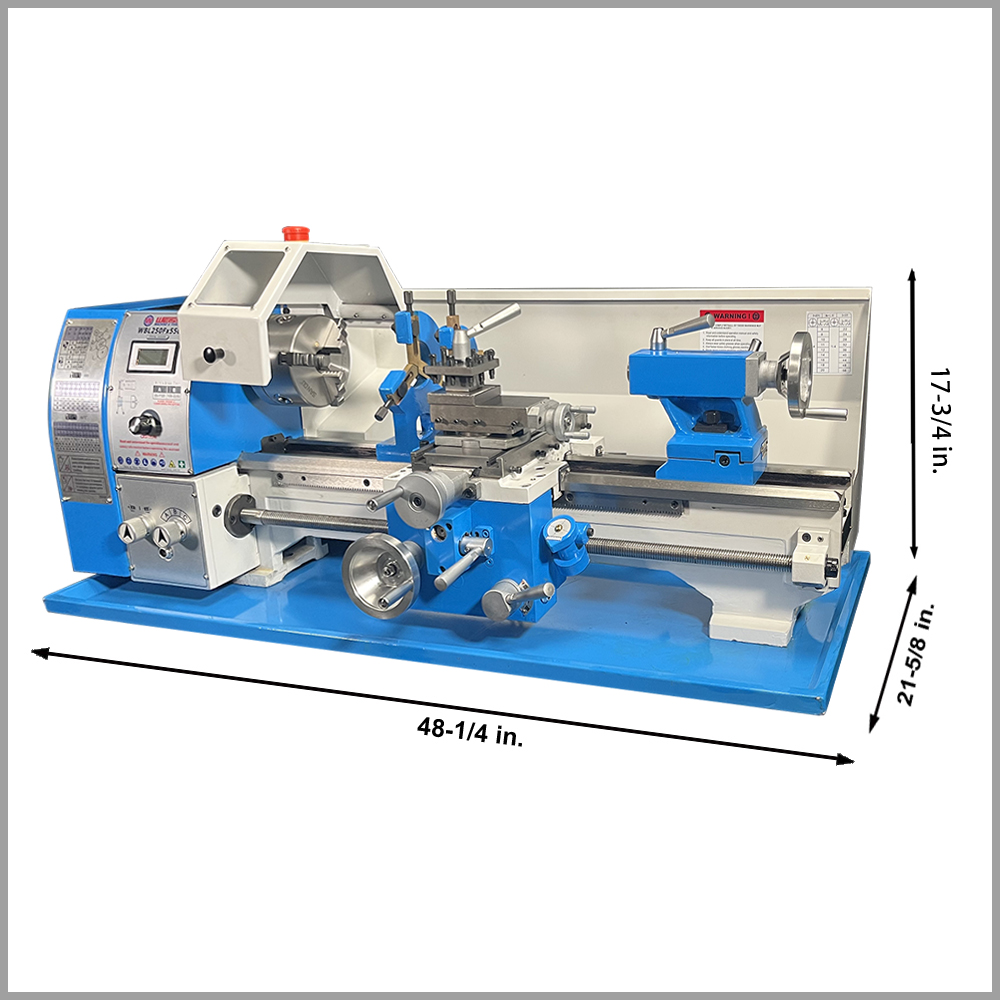

Despite its compact benchtop design, the WEISS WBL250F offers an impressive turning capacity. With a swing over bed of 10 inches and a distance between centers of 22 inches, this lathe accommodates a wide range of workpieces. Whether you’re working on small-scale projects or larger pieces, the WEISS WBL250F provides ample space for your machining needs.

Versatility and Expandability:

The WEISS WBL250F is equipped with a variety of features that enhance its versatility. The lathe includes both metric and imperial thread cutting capabilities, allowing you to work with different thread standards. Additionally, the lathe’s spindle is compatible with a wide range of chucks and accessories, enabling you to expand its functionality and tackle an even broader array of projects.

Conclusion:

The WEISS WBL250F Metal Lathe is a testament to superior engineering and craftsmanship. With its precision, power, and user-friendly operation, this benchtop brushless lathe is a valuable addition to any workshop. Whether you’re a professional machinist or a passionate hobbyist, the WEISS WBL250F empowers you to create intricate designs, achieve remarkable precision, and unleash your creativity. Invest in the WEISS WBL250F Metal Lathe today and experience the joy of exceptional machining performance.

Technical Details

Model No. WBL250F

· Distance between centers: 22“

· Swing over bed: 10“

· Swing over cross slide: 5-1/2“

· Bed width: 5-1/4“

· Spindle bore: 1″

· Spindle taper: MT#4

· Spindle speeds: 50-2000 RPM (Variable)

· Range of cross feeds: 0.0014-0.004“/rev.

· Range of longitudinal feeds: 0.0025-0.014“/rev.

· Inch thread range: (37) 8–80 TPI

· Metric thread range: (21) 0.35–3 mm

· Cross slide travel: 4-1/8“

· Compound rest travel: 2-3/4″

· Tailstock taper: MT#2

· Tailstock quill travel: 2-3/4“

· Motor type: Brushless 1.5HP

· Power supply: 110V/1Ph/60Hz

· Rated current: 10A

· Packing size: 49-1/4” W × 22-5/8” D × 24” H

· Approx. shipping weight: 350 lbs.

Standard Accessoris

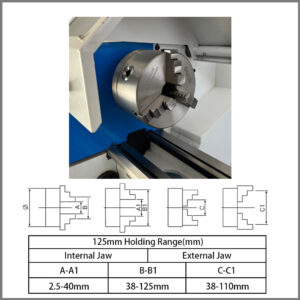

· 5” A type 3-jaw chuck with two sets of jaws

· Steady rest

· Follow rest

· Faceplate

· 4-way tool post

· Chuck guard

· Splash guard & oil tray

· Chasing thread dail

· Replacement fuses

· MT#2 & MT#4 dead centers

· MT#2 living center

· Tool box with service tools

Introducing the Power Cross Feed Feature of the WEISS WBL250F Metal Lathe: Enhancing Precision and Efficiency in Your Machining Projects

The WEISS WBL250F Metal Lathe is a versatile and high-performance machine designed to meet the needs of both professionals and hobbyists. One of its standout features is the power cross feed capability, which significantly enhances the precision and efficiency of your machining projects. Let’s delve into the details of this exceptional feature and understand how it can benefit your work.

Effortless Cross Feed Movement:

The power cross feed feature of the WEISS WBL250F allows the cutting tool to move automatically across the workpiece during machining operations. This eliminates the need for manual adjustment, providing effortless and consistent movement. By automating the cross feed, you can achieve smoother and more precise cuts, reducing the chances of errors or inconsistencies in your work. This feature is particularly advantageous when working on complex or intricate designs that require precise and steady tool movements.

Improved Accuracy:

With the power cross feed feature, the WEISS WBL250F ensures improved accuracy in your machining projects. The automated movement of the cutting tool eliminates the human factor, which can sometimes introduce slight variations or deviations in manual adjustments. By relying on the precise and repeatable power cross feed mechanism, you can consistently achieve accurate cuts, resulting in higher-quality finished products. This feature is especially beneficial when working on projects that demand tight tolerances or require intricate detailing.

Time and Energy Savings:

The power cross feed feature of the WEISS WBL250F not only enhances precision but also saves you valuable time and energy. With manual cross feeding, you would need to constantly adjust the tool position during machining, which can be time-consuming and physically demanding. By automating this process, the power cross feed feature streamlines your workflow, allowing you to focus on other aspects of your project. It significantly reduces the time required for repetitive tasks, enabling you to complete your work more efficiently.

Versatility and Flexibility:

The power cross feed feature adds to the versatility and flexibility of the WEISS WBL250F Metal Lathe. It allows you to work on a wide range of materials, from soft plastics to tough metals, with ease and precision. Whether you’re turning, facing, or threading, the power cross feed feature ensures consistent and reliable tool movement, enabling you to tackle diverse machining projects. Additionally, you have control over the feed rate, allowing you to adapt to different materials and achieve optimal results.

The power cross feed feature of the WEISS WBL250F Metal Lathe revolutionizes your machining experience by providing effortless and accurate tool movements. It saves you time, enhances precision, and adds versatility to your projects. With this feature, you can take on intricate designs, work with various materials, and achieve consistent, high-quality results. Invest in the WEISS WBL250F Metal Lathe and unlock the power of power cross feed for unparalleled precision and efficiency in your machining endeavors.

Detail important parts for best precision

Variable Speed Control Benefits

Precise Speed Control: The Electronic Driving System of the WEISS WBL250F allows for precise speed control, enabling you to match the rotational speed of the spindle to the specific requirements of your machining task. With the ability to adjust the speed electronically, you have fine-grained control over the cutting process, ensuring optimal performance and the desired results. This precise speed control is especially crucial when working with different materials or when executing intricate turning or threading operations.

Precise Speed Control: The Electronic Driving System of the WEISS WBL250F allows for precise speed control, enabling you to match the rotational speed of the spindle to the specific requirements of your machining task. With the ability to adjust the speed electronically, you have fine-grained control over the cutting process, ensuring optimal performance and the desired results. This precise speed control is especially crucial when working with different materials or when executing intricate turning or threading operations.

Variable Speed Range: The electronic driving system of the WEISS WBL250F offers a wide variable speed range, allowing you to adapt to various machining applications. With the flexibility to adjust the speed according to your specific needs, you can efficiently work with a diverse range of materials, from soft plastics to tough metals. Whether you require high-speed operations or slower, more controlled cutting, the variable speed range of the electronic driving system has you covered.

Smooth and Consistent Operation:

The Electronic Driving System ensures smooth and consistent operation throughout your machining projects. It minimizes vibrations and eliminates sudden speed fluctuations, resulting in stable and reliable performance. This stability is crucial for achieving precise cuts and maintaining consistent surface finishes, particularly when working on delicate or complex workpieces. The smooth and controlled operation enhances the overall quality of your work and reduces the need for rework or corrections.

Digital Display and User-Friendly Interface:

The WEISS WBL250F Metal Lathe’s Electronic Driving System features a digital display and user-friendly interface, making it easy to monitor and adjust the lathe’s settings. The digital display provides clear and accurate RPM readouts, allowing you to keep track of the spindle speed in real-time. The user-friendly interface ensures effortless navigation and quick adjustments, enhancing your productivity and minimizing downtime. This intuitive control system makes the WEISS WBL250F Metal Lathe accessible to both seasoned professionals and novice machinists.

Energy Efficiency:

The Electronic Driving System of the WEISS WBL250F incorporates energy-efficient technology, optimizing power consumption without compromising performance. By utilizing electronic controls, the system minimizes energy waste and reduces operating costs. This eco-friendly feature not only benefits the environment but also ensures economical operation of the lathe, making it a sustainable choice for your workshop.

Important Benefits of the Change Gear System in the WEISS WBL250F Metal Lathe:

The WEISS WBL250F Metal Lathe is equipped with a robust and efficient change gear system, offering a range of important benefits that enhance the versatility and functionality of the lathe. Let’s explore these benefits in detail:

1. Wide Thread Cutting Capabilities:

The change gear system in the WEISS WBL250F is designed to provide a wide range of threading options. With its all-metal gears, this lathe offers 33 different inch thread cutting options and 21 metric thread cutting options. This extensive selection allows you to work with various thread standards, giving you the flexibility to tackle diverse projects and meet specific threading requirements.

2. Precise and Accurate Thread Cutting:

The change gear system ensures precise and accurate thread cutting in the WEISS WBL250F. The use of high-quality metal gears guarantees durability and smooth gear engagement, resulting in consistent and reliable threading performance. This precision is essential for achieving accurate thread profiles, maintaining thread pitch, and ensuring proper fitment with corresponding mating parts.

3. Protective QKS8 Door Switch:

The WBL250F change gear cover is equipped with a protective QKS8 door switch, providing an important safety feature. This switch ensures that the lathe’s change gear system remains securely covered during operation, preventing accidental access to moving parts. It helps create a safer working environment by minimizing the risk of injury and protecting the integrity of the change gear system.

4. Versatile Machining Applications:

The change gear system in the WEISS WBL250F expands the lathe’s versatility by enabling a wide range of machining applications. Whether you’re working on small-scale or large-scale projects, the ability to cut both inch and metric threads allows you to accommodate various workpiece sizes and thread specifications. This versatility enhances your capabilities and broadens the scope of projects you can undertake.

5. Durable and Long-lasting Performance:

The all-metal gears used in the change gear system of the WEISS WBL250F ensure durability and long-lasting performance. Metal gears are more resistant to wear and tear compared to their plastic counterparts, allowing them to withstand the rigors of regular use and heavy machining tasks. This durability translates into a longer lifespan for the change gear system, minimizing the need for frequent replacements or repairs.

6. Reliable and Repeatable Results:

With the change gear system in the WEISS WBL250F, you can rely on consistent and repeatable results in your thread cutting operations. The well-engineered design and precise gear ratios enable you to replicate thread patterns accurately, ensuring uniformity across multiple workpieces. This reliability is essential for maintaining product quality, meeting customer specifications, and achieving efficient production processes.

The change gear system in the WEISS WBL250F Metal Lathe offers a multitude of benefits that enhance its versatility, accuracy, and safety. From providing a wide range of thread cutting options to ensuring durable performance and protecting the operator, the change gear system plays a crucial role in optimizing your machining experience. Invest in the WEISS WBL250F Metal Lathe and unlock the advantages of its robust change gear system for precision threading and versatile machining capabilities.

The importance of having a guideway that is induction hardened and precision ground in a bench lathe, such as the WEISS WBL250F, cannot be overstated. Let’s explore the key reasons why this feature is crucial:

1. Enhanced Stability and Rigidity:

The induction hardening process involves treating the guideway with heat, which results in a hardened surface. This hardened surface improves the overall stability and rigidity of the guideway. As a result, it reduces flexing or bending during machining operations, ensuring that the tool and workpiece remain securely positioned. This enhanced stability is essential for achieving accurate and consistent cuts, particularly when working with tight tolerances or intricate designs.

2. Reduced Wear and Lon life:

Precision grinding of the guideway creates a smooth and flat surface. This minimizes friction and wear between the moving parts, such as the carriage and the guideway. The induction hardening adds an extra layer of durability, making the guideway more resistant to wear and damage over time. The combination of precision grinding and induction hardening extends the lifespan of the guideway, reducing the need for frequent maintenance or replacements.

3. Improved Accuracy and Precision:

The precision ground and induction hardened guideway ensures precise and repeatable movements of the carriage along the lathe’s bed. This accuracy is crucial for achieving consistent results, whether you’re turning, facing, or threading. The smooth and flat surface of the guideway, along with its enhanced stability, reduces any potential deviations or vibrations during machining, resulting in high-quality finished products and improved overall precision.

4. Reduced Vibration and Improved Surface Finish:

Vibration can negatively impact the surface finish of machined parts. With an induction hardened and precision ground guideway, the amount of vibration transmitted to the workpiece is significantly reduced. This reduction in vibration allows for smoother cutting and turning operations, resulting in improved surface finishes. Whether you’re working with delicate materials or aiming for a polished surface, the quality of the guideway plays a critical role in achieving the desired results.

5. Consistency and Repeatability:

The induction hardened and precision ground guideway ensures consistency and repeatability in your machining operations. The uniformity of the guideway’s surface, along with its enhanced stability and reduced wear, allows for precise and repeatable movements of the carriage. This consistency is vital when machining multiple parts or when replicating specific cuts, ensuring that each piece meets the required specifications with accuracy and reliability.

In summary, having a guideway that is induction hardened and precision ground in a bench lathe like the WEISS WBL250F provides enhanced stability, reduced wear, improved accuracy, reduced vibration, and increased longevity. These factors contribute to the overall performance, precision, and longevity of the lathe, enabling you to achieve superior machining results.

Reviews

There are no reviews yet