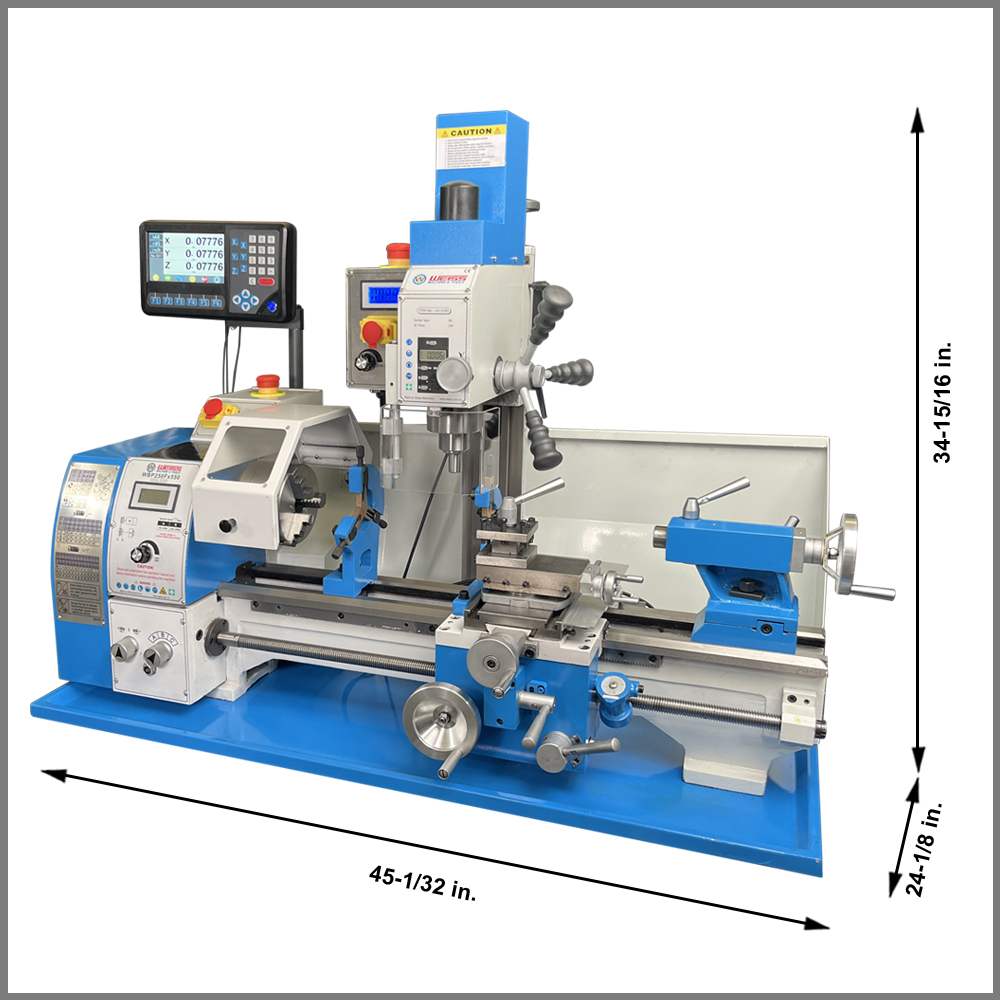

WEISS WBP250F-D 10″x22″ Variable-Speed Combination Lathe/Mill with 3-axis DRO

The WEISS WBP250F-D Lathe/Mill combination unit is a smart choice for those seeking efficient part machining without the need for a large workshop space.

The WBP250F-D combines a variable-speed milling head with the lathe, offering the versatility of two metalworking machines in one. It comes fully equipped with work-holding and tool-holding accessories, allowing you to perform tasks such as turning, drilling, milling, chambering, boring, and facing with ease.

Enjoy the convenience of real inch leadscrews and feed screws, eliminating the need for metric conversions and ensuring precise and straightforward measurements.

Experience the convenience of power cross-feed functionality.

Equipped with powerful brushless motors for both the lathe and mill, the WBP250F-D delivers reliable performance.

The included 3-axis DRO system provides real-time information on carriage travel, cross-slide travel, and milling head travel, enhancing precision and accuracy.

Designed for 110V single-phase, 60Hz input power, ensuring compatibility with standard power sources.

When you choose WEISS, you gain access to a factory known for delivering dependable quality, timely service, and rapid technical support. For top-quality products from China at the best prices, WEISS is your destination for excellent value!

Specifications:

Model No. WBP250F

Item No. 10103255

LATHE SPECIFICATIONS:

· Distance between centers: 22″

· Swing over bed: 10″

· Swing over cross slide: 5-1/2″

· Bed width: 5.3″

· Spindle bore: 1″

· Spindle taper: MT#4

· Spindle speeds: 50-2000 RPM (Variable)

· Range of cross feeds: 0.0014-0.004″/rev.

· Range of longitudinal feeds: 0.0025-0.014″/rev.

· Inch thread range: (37) 8–80 TPI

· Metric thread range: (21) 0.35–3 mm

· Cross slide travel: 4-1/8″

· Compound rest travel: 2-3/4″

· Tailstock taper: MT#2

· Tailstock quill travel: 2-3/4″

· Motor type: Brushless 1.5HP

· Power supply: 110V/1Ph/60Hz

· Rated current: 10A

MILL SPECIFICATIONS:

· Drilling capacity: 5/8″ (steel)

· End milling capacity: 5/8″

· Spindle taper: R8

· Spindle travel: 2″

· Spindle speeds: 100-2250 rpm (Variable)

· Distance from spindle to table: 9.45″

· Distance from spindle to bed: 11.3″

· Head tilt: 90° Left/Right

· T-slots: two at 3/8″, 3.937″ on center, 10″ long

· Drawbar: 7/16-16 TPI, 9-5/8″ L

· Motor type: Brushless, 1HP

· Power supply: 110V/1Ph/60Hz

· Rated current: 10A

MAIN SPECIFICATIONS:

· Packing size: 49″ W × 25″ D × 37″ H

· Approx. shipping weight: 607 lbs.

WBP250F Weiss Machine Metalworking operations:

Turning: You can use the lathe functionality to turn cylindrical parts. For instance, you can create precise shafts, pins, or bushings by rotating the workpiece against a cutting tool.

Milling: With the variable-speed milling head, you can perform milling operations. For example, you can machine flat surfaces, slots, keyways, and pockets on a workpiece. Milling is great for creating complex shapes and contours.

Drilling: The machine allows for drilling holes with accuracy. Whether you need to drill through-holes or create precise, deep bores, the WBP250F-D can handle it.

Chambering: You can use the machine to chamber firearm barrels or create chambers for other applications. This requires precise control over the cutting tool and spindle speed.

Boring: Boring operations involve enlarging existing holes or creating precise internal diameters. This machine can bore holes in a workpiece with ease.

Facing: Facing is the process of smoothing and squaring the end of a workpiece. You can face parts to ensure they have flat and even surfaces.

Threading: While not mentioned explicitly, some combination lathe/mill machines also have threading capabilities. You can create threads on cylindrical parts, allowing for threaded connections.

Knurling: If equipped with a knurling tool, you can add knurling patterns to the surface of parts for improved grip or aesthetics.

Tapering: You can create tapered parts by adjusting the tool’s angle and feed rate. Tapered components are often used in various applications, such as for fitting into tapered holes or creating conical shapes.

Grooving: This operation involves cutting narrow grooves or slots into a workpiece. It’s commonly used for adding features like retaining rings or for creating keyways.

These examples demonstrate the versatility of the WEISS WBP250F-D Lathe/Mill combination unit, allowing machinists to perform a wide range of metalworking operations with precision and efficiency.

Advanced Electronic Driving System:

Unlock the Potential of Precision Machining with the WBP250F-D’s Electronic Driving System:

- Robust Power Delivery: The WBP250F-D boasts an impressive 1.5HP high-performance brushless motor for the lathe, coupled with a 1HP brushless motor for the mill. These motors ensure optimal power output while operating in near silence, setting new standards for precision machining.

- Enduring Reliability: Experience long-term reliability thanks to the incorporation of high-quality electronics throughout the machine’s architecture. These components are meticulously selected to guarantee consistent and dependable performance, elevating your machining endeavors to a new level of excellence.

- Enhanced Electrical Stability: The integration of braking resistors enhances the stability of the electrical system, providing you with the peace of mind that your machine will operate smoothly and safely, even during demanding machining tasks.

- Efficiency Redefined: Our brushless motors are renowned for their exceptional efficiency, minimal noise emissions, seamless operation, extended lifespan, and minimal maintenance requirements. Moreover, their low energy consumption translates into substantial cost savings for users, making the WBP250F-D a sound economic choice for precision machining operations.

Elevate your machining capabilities with the cutting-edge Electronic Driving System of the WBP250F-D. Achieve unparalleled precision, reliability, and efficiency in your metalworking projects. Don’t miss out on the opportunity to harness the full potential of this advanced technology for your machining needs.

Reviews

There are no reviews yet